Today I would like to share with you through this article how we can visualize where technology is taking us, because it is rapidly encompassing all commercial areas, improving the quality of life and allowing us to revolutionize traditional models that we are accustomed to using. Technology is present in many of the acts we carry out throughout the day and at this time is already the order of the day in the kitchen.

There is a new and revolutionary restaurant in Boston called Spyce where chefs are robots and cook food in 3 minutes or less.

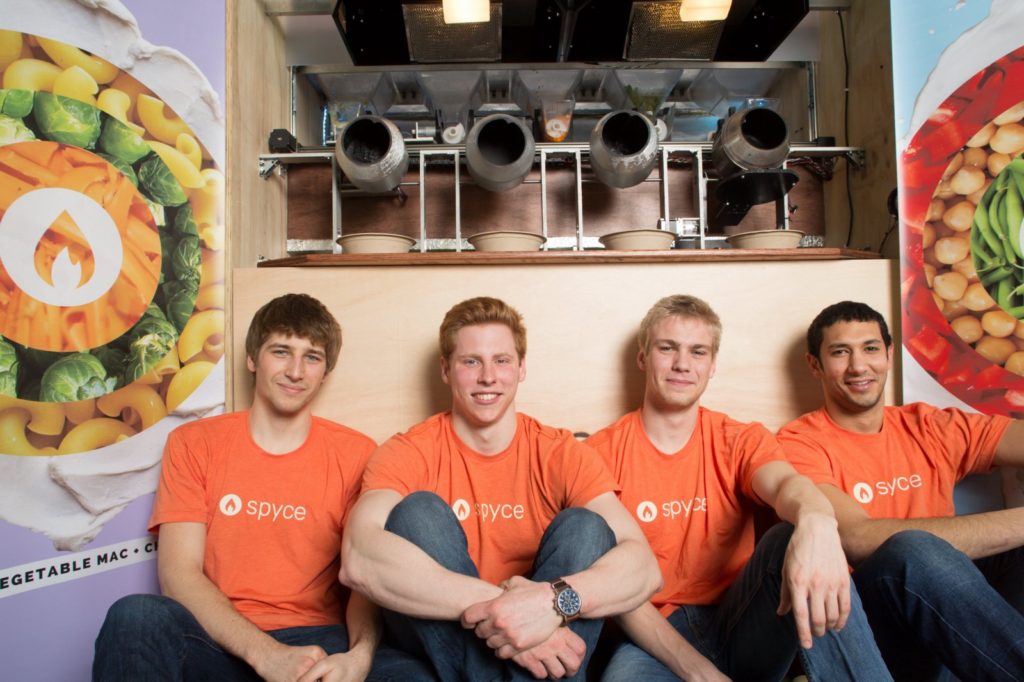

Four students from MIT (Massachusetts Institute of Technology) Michael Farid, Brady Knight, Luke Schlueter and Kale Rogers created the robotic technology and restaurant concept while at the University. Known as the “Spyce Boys”, the founders were inspired by their experiences as hungry students and athletes with tight budgets.

The idea of formulating this innovation was born at MIT where they thought, “We are hungry students and water polo teammates tired of spending $ 10 on lunches and dinners. Our athletic appetites required better nutrition, but the budgets of the students did not allow that kind of expense. In this way, we wanted fast, cheap and healthy food, and we could not unite all three,” Kale Rogers said in an interview with the BBC. The inspiration of the founders for this business came to them as something natural.

We were all engineers obsessed with robotics, so we stopped barking and built one in our fraternity basement. “Two years and many burns, bruises and Brussels sprouts afterwards, we are opening our first restaurant and we could not be more excited”.

The four graduates of the Massachusetts Institute of Technology (MIT) have applied their knowledge of robotics and engineering to found Spyce, a restaurant whose dishes are prepared between robots. During the first month, they served more than 10,000 meals in Boston.

While these four young entrepreneurs perfected their automated kitchen technology, they knew they needed more than technical knowledge to successfully develop a robotic restaurant. So Michael Farid got in touch with specialist Daniel Boulud, the chef and owner of several award-winning restaurants and author of nine cookbooks. The team finally convinced him to enter as Spyce’s culinary director and invest in the concept. Boulud introduced them to Sam Benson, who had worked for him at Café Boulud, with a Michelin star, in New York and who had done research and development at Chipotle. The “Spyce Boys” as the four are called in jest, were delighted when he signed up as executive chef.

Chef Sam Benson comments “The experience of the robotics kitchen, the food and the vision of the Spyce team exceeded my expectations. His passion and innovation needed a strong commitment to ingredients and excellent recipes, for that reason they have convinced me” he told BBC News.

How did you consolidate your idea?

In 2015, when Kale Rogers and Brady Knight were junior students and Michael Farid was with his master’s degree studies, they signed up for StartMIT, an intensive entrepreneurship workshop offered during the Independent Activities Period (IAP). They agreed that their goal would be to prepare fast, delicious and healthy food that someone with a student budget could afford. Luke Schlueter joined the team, later that year. Each of the four had previously received product design and robotics classes between 2007 and 2009. Three of them had taken them together, co-developing a robot that kicked a soccer ball. Maybe it was not a surprise, then, that they would soon build their first kitchen robot, working in the basement of what is now the home of the Theta Tau fraternity.

The original IAP prototype, says Brady Knight, “only worked on the videos”. The mechanism of the hopper, in particular, needed adjustments. The IAP version, which used a pizza cutter attached to an engine to drop ingredients in a wok, “just sprayed quinoa everywhere” he says.

When the team built a second prototype that summer as part of the summer accelerator of the Martin Trust Center for Entrepreneurs (USA) (then known as Founders Skills Accelerator and now MIT delta v), they had relied on their experiences in class.

Even so, his food processor was still a work in progress. That fall, he tossed the semi-cooked food directly to the counter in front of a potential investor. The result of this fiasco is that now each of the restaurant’s automated woks contains a sensor that confirms if a bowl is underneath. Eager to continue improving their prototype, Knight and Rogers then attended a course where they learned to perform exhaustive experiments.

After failing several times with his prototype they managed to improve it and Spyce won the Lemelson-MIT Student Award (in the “Eat It” category) and the Public Award of the Entrepreneurship Competition of MIT $ 100 USD (One Hundred Thousand Dollars).

How does this robotic kitchen work?

The boys devised this concept in a totally innovative way.

As customers order their orders via touchpads, Spyce’s automated food storage containers (known as hoppers) reliably introduce refrigerated ingredients through a dosing system of portions that measure precise quantities in a red box that closes along a horizontal track. That box, called the corridor, collects the ingredients and delivers them to one of the seven induction cooking woks that rotate to mix the food and cook evenly at 450 ° F (about 232 ° C). Hoppers look like simple funnels, but Kale Rogers says: “some things in there are patented, and to develop them required many iterations”. The screens, located on the woks, complete the visible technology and offer customers progress reports on their foods.

Spyce has a test kitchen in Greentown Labs, an incubator in Somerville, Massachusetts (USA), for startups focused on clean technology. And it has a large food preparation space in Malden, Massachusetts (USA), where people wash and chop the fresh ingredients overnight. The three sites together employ dozens of workers. “Automating workers is not our angle,” says Brady Knight. On the contrary, he argues, Spyce has transferred a lot of heavy work from humans to machines for the sake of efficiency, and claims that the remaining jobs for humans are paid better than typical fast-food jobs.

When a client arrives at the restaurant a guide greets and helps with the touch screen kiosks, which allow them to customize any of the seven basic bowls: Latin, Thai, Indian, Moroccan, chicken + rice, crucible and Lebanese, adding and discarding ingredients such as avocado, toasted green wheat and tender green leaves.

Customers often spend more time wavering on the touch screen over what dish to order, add or remove, which Spyce needs to cook the food. In 3 minutes after inserting the credit card in a kiosk, the ordered food is delivered. A standard bowl, which includes three or four optional trimmings, will cost you $ 7.50 USD. The robotic kitchen can make up to 200 meals per hour, almost the same number as in conventional fast food restaurants.

What is your future?

A month after its opening, the restaurant had served more than 10,000 meals. The business continued is growing rapidly. Sam Benson, the chef, worked on the “R & D menu” (developing innovative seasonal menus). The Spyce Boys, as they are called, were building a mobile application for placing orders in advance.

In an interview with BBC News, when asked what made these four mechanical engineering specialists believe they could develop a commercially viable robotic kitchen, he had to stop and think. “Ten years ago, it was not possible to do this, the tools we use are quite new” says Brady Knight, referring to the switches and controllers that allowed them to quickly create the Spyce kitchen prototype and build it at a sufficiently low price.

The Spyce restaurant concept continues to grow in Boston and is expected to open in other cities in the United States and other countries, as it has made the processes of the kitchen even more efficient. Of course, robots in the food industry have not always succeeded: after all, a restaurant in China recently got rid of all the machine’s staff after realizing that they simply could not meet the needs of their customers. But maybe, this robot kitchen is the alternative to fast food restaurants we’ve been looking for.

COMMENTS